Call Us On

+91 22 42029999

Welcome to Kamsons

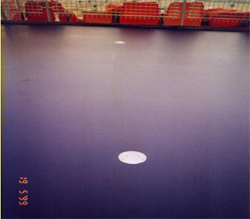

KAMTHANE AQUA COLOUR TOP is a U.V. stable high performance aqueous Aliphatic polyurethane floor coating for various Industries.

KAMTHANE AQUA COLOUR TOP is a complex blend based on urethane polymers which produces systems with outstanding abrasion, impact and chemical resistance coupled with high degree of flexibility and is micro-porous allowing the substrate to breathe, unlike solvent based systems.

KAMTHANE AQUA COLOUR TOP is a polyurethane pre mixed hard wearing yet flexible surface coating designed for the long term protection of Industrial floors in factories, warehouses, car park decks, diaries, breweries, hygienic coatings for pharmaceuticals where long term maintenance-free protection is required.

KAMTHANE AQUA COLOUR TOP is produced to a silk sheen for maximizing light reflectivity whilst retaining easy to clean, non slip characteristics and reduction of glare.

KAMTHANE AQUA COLOUR TOP Systems are colour co-ordinated in the standard for optimum visibility of direction, line and parking bays and speed bump markings.

KAMTHANE AQUA COLOUR TOP adhesion to sub floor is not affected due to moisture, as it is a breathable water based system unlike its counterpart solvent based systems and is available in different shades.

Clean the surface of all loose gravel, dirt, grease, oil and foreign matters with high pressure wash, for a good bond with the sub-floor. Prior to application, large blisters and surface breaks shall be slit and opened for the release of entrapped moisture then cemented properly wherever necessary.

Apply a primer coat using medium pile roller or similar with KAMTHANE PU PRIMER Followed with two coats ofKAMTHANE AQUA COLOUR TOP. It is extremely important to ensure that the previous coat is completely dry before application of next coat depending on the weather conditions. The coating should be applied evenly over the surface to ensure a regular film thickness. A final glossy/matt clear top coat to be applied with KAMTHANE K- 1492. Curing time of approx 72-120 hours depending on weather conditions is needed before allowing traffic or any further works.

Coverage : 6-8 sq.mts. for 2 coats per litre.

KAMTHANE AQUA COLOUR TOP will resist spillages of:

| Type | : | anionic urethane hybrid, dispersion |

| Appearance | : | white translucent bluish. |

| Total solids (% w/w) | : | 35% ± 1 |

| pH (25°C) | : | 7.5 -9.0 |

| Viscosity, cps | : | 40 -160 |

| Volatile | : | 6.5 % NMP |

| Density of dipsersion (kg/l) | : | 1.04 |

| Elongation at break | : | 190% |

| Konig hardness | : | 150 |

| Freeze/thaw stability | stable |