|

HIGH STRENGTH WATERPROOFING COMPOUND AND BONDING AGENT

DESCRIPTION

SEALTITE is an aqueous Acrylic Co-polymer emulsion specially

formulated for use with cement. SEALTITE modifies the

property of cement in mortars and in concrete to make them

perform better in terms of water proofing, repair, corrosion

inhibition, bonding, durability and wear resistance.

PRIMARY USES

1) Corrosion protection of steel.

2) Floor screed and topping.

3) Concrete and floor screed repairs.

4) Water proofing and tanking of basements.

5) Bonding old concrete to new concrete.

ADVANTAGES

Water resistant, excellent adhesion to concrete, steel,

brick, stones, compatible with cement. High compressive,

tensile and flexural strength. Resistant to ingress of

salts, mineral oils etc. Non toxic. Suitable foruse in

potable water tanks. Excellent corrosion protection.

Economical when compared with epoxy mortars.

DIRECTIONS FOR USE

A) Method:

1) On a cleaned and prepared surface apply SEALTITE bonding

slurry.

2) Apply SEALTITE modified mortar by float or trowel to form

an uniform smooth surface. Bonding slurry sets very fast

hence modified mortar application should be fast and

immediately after application of bonding slurry.

3) Moist cure for 24 hours and then allow it to dry off.

B) Preparation:

Bonding Slurry = Cement + SEALTITE

1 + 1

NOTE: Applied bonding slurry sets very fast. 1 LTR SEALTITE

with 1 kg of cement gives a slurry which covers 25 to 30

sq/ft. on smooth even surface.

MODIFIED MORTAR

Cement

l kg

Zone II dry Sand

2.6kg

SEALTITE

200ML

Water

150ML

Yield

1.30 Litres

This mortar covers 7 sq.ft.area if applied to a thickness of

10mm

Note: 1) This mortar looks very dry. No further addition of

SEALTITE or water is to be made.

2) Dosage of SEALTITE can be varied between 5 ltrs to 15

ltrs. per 50kg bag of cement depending upon application and

severity of problem. 2lts per 50kg bag of cement is used in

general plaster only as an admixture to produce crack free

plaster.

TYPICAL APPLICATIONS :

1) Corrosion Repairs of Beams, Columns and Slabs:

a) Remove the cover concrete and cutback to the sound

concrete zone.

b) Remove all the rust from the reinforcement by mechanical

means.

c) Apply one coat of SEALTITE bonding slurry on the

reinforcement and the surrounding concrete surface.

d) When the bonding slurry is still tacky apply modified

mortar by pressing in position using 10 litre SEALTITE per

50kg bag of cement. Modified mortar can be applied upto a

thickness of 20mm. For building up to higher thickness leave

the first layer to dry overnight and apply second layer with

one more coat of bonding slurry.

e) Moist cure for 24 hours and allow it to dry off.

2) Industrial Floor or Floor Duct Nosing Repair:

a) Cutback to sound concrete surface and make the surface

wet.

b) Apply the bonding slurry and when it is still wet apply

the SEALTITE modified mortar using

10 litre of SEALTITE per 50 Kg bag of cement

c) Feather edge to match the original floor level. In case

of nosing carefully build up the edge and

give a smooth finish.

d) Moist cure for 24 hours and allow it to dry off.

3) Bonding old Concrete to New Concrete:

a) Vertical Joint: Apply SEALTITE bonding slurry on the

prepared wet old concrete vertical surface

and pour the concrete.

b) Horizontal joint: Pour and spread SEALTITE bonding slurry

on the wet old concrete surface to a

thickness of 3.5 mm and pour fresh concrete.

4) Plaster & Screed Mortars:

SEALTITE is admixed at a dosage of 2 litres per 50 kg bag of

cement to improve properties of general plaster and screed

free from shrinkage crack and for achieving higher

compressive and tensile strength. Screeds over water

proofing membranes and patch up repairs before application

of water proofing membranes are done with SEALTITE admixed

mortars.

|

|

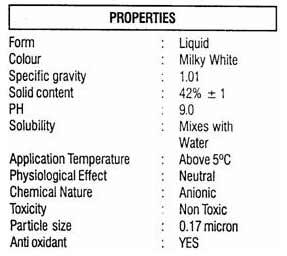

Technical

Specification

Typical

Engineering Data

Physical

Properties of SEALTITE

Appearance - Free flowing white liquid - dries off to

colourless

Sp.

gravity - 1.01

Shelf

life - 1 year in unopened

containers

Typical

Result of SEALTITE

Modified

Portland Cement Mortar

Compressive Strength ASTM C190

(50 mmm)

cubes

3

days - 210 kg/cm2

7 days -

280 kg/cm2

28 days -

340 kg/cm2

Flexural

Strength ASTM C190

28 days - 90

kg/cm2

Bond

Strength ASTM C-78

14 days - 80 kg/cm2

|